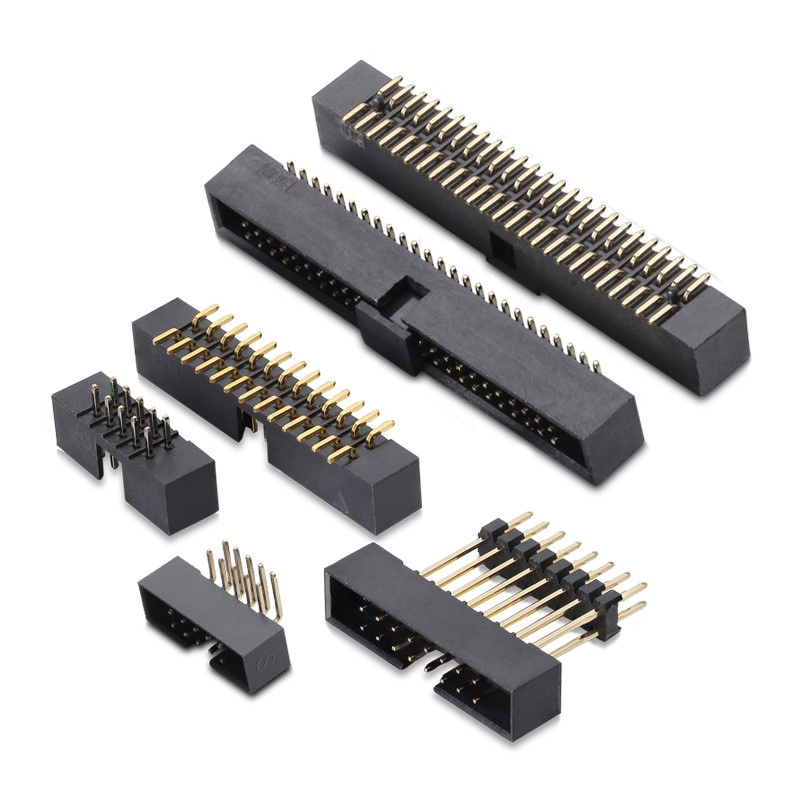

Box Header Connector

1.0mm Simplified Box Header

1.27mm Box Header Connector

-

-

-

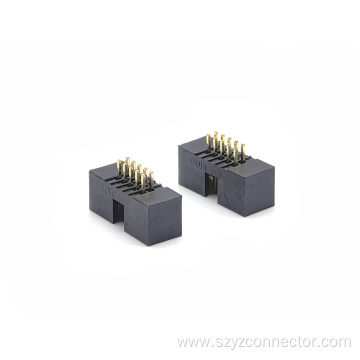

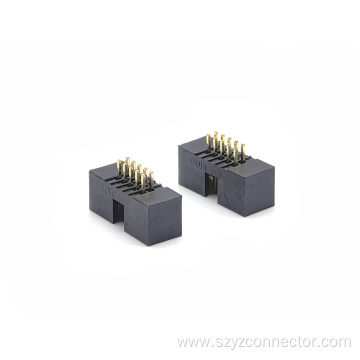

1.27mm Box Header Connector Dual Row Straight

Contact Now

-

-

-

1.27mm Pitch Box header Connector Straight H5.4mm

Contact Now

-

-

2.0mm Box Header Connector

-

-

-

-

-

2.0mm Pitch Box header Connector SMT H4.8mm

Contact Now

-

2.0mm Pitch Box header Connector Right Angle

Contact Now

-

-

2.0mm Pitch Box header Connector Straight 50P

Contact Now

2.54mm Box Header Connector

-

-

2.54mm Pitch Box header Connector Straight 26P

Contact Now

-

-

2.54mm Pitch Box Header Connector Straight 40P

Contact Now

-

-

2.54mm Box header Connector Dual Row Straight

Contact Now

-

-

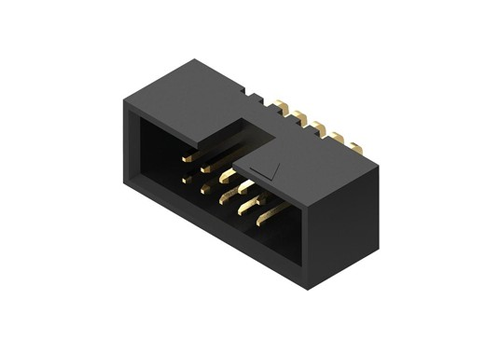

2.54mm Pitch Box header Connector SMT H10.32mm 2*3P

Contact Now

The Box Header Connector is a versatile and essential electronic connection component. It features a box - shaped header design, which provides excellent mechanical protection and stability for the pins. Crafted with high - quality copper materials for pins and durable engineering plastics for the housing, it ensures reliable electrical conductivity and long - term performance. The connector's standardized interface design allows for easy integration with a wide range of mating connectors, simplifying the assembly process of electronic devices.

How to choose the appropriate pitch for my Box Header Connector?

Choose according to the space of the circuit board and the requirements of connection density. If the space is compact and high - density connection is required, a 1.27mm pitch can be selected; for general applications, a 2.0mm or 2.54mm pitch is recommended, which has better compatibility. Also, refer to the pitch specifications of the mating connector to ensure a match.

What should I do if the connector shows signs of overheating during operation?

Stop using it immediately and check for overloading, poor contact, or poor heat dissipation. Ensure good ventilation around the connector, and you can install a heat sink to assist with heat dissipation. If the problem persists, contact the supplier for inspection and repair.

Can this connector be used in a corrosive chemical environment?

The standard model is not suitable for strong corrosive chemical environments. If it needs to be used in such environments, you can choose models with special anti - corrosion coating treatment. This coating can resist the erosion of various chemical substances. At the same time, regularly check the corrosion status of the connector and maintain it in a timely manner.

How to ensure accurate soldering for surface - mount Box Header Connectors?

Use a PCB board with positioning marks and rely on the visual recognition system of the pick - and - place machine for placement. Before soldering, evenly apply an appropriate amount of solder paste on the pads. Strictly control the reflow soldering temperature curve and time. It is recommended that the peak temperature is 250℃ - 260℃ and the reflow time is 5 - 8 minutes.